Designing and making with Jesmonite

This month we introduce our new Jesmonite Tile Collection - beautifully minimal multi-purpose essentials that will fit your office as well as your bathroom.

Hand-poured in our studio, this water-based, non-solvent material allows us to craft beautiful products in an environmentally-conscious way, keeping our carbon footprint low without compromising design.

The collection is wonderfully tactile, with a smooth, cool stone-like texture. Each piece is handmade and unique.

We're sharing more about the designing and making process below...

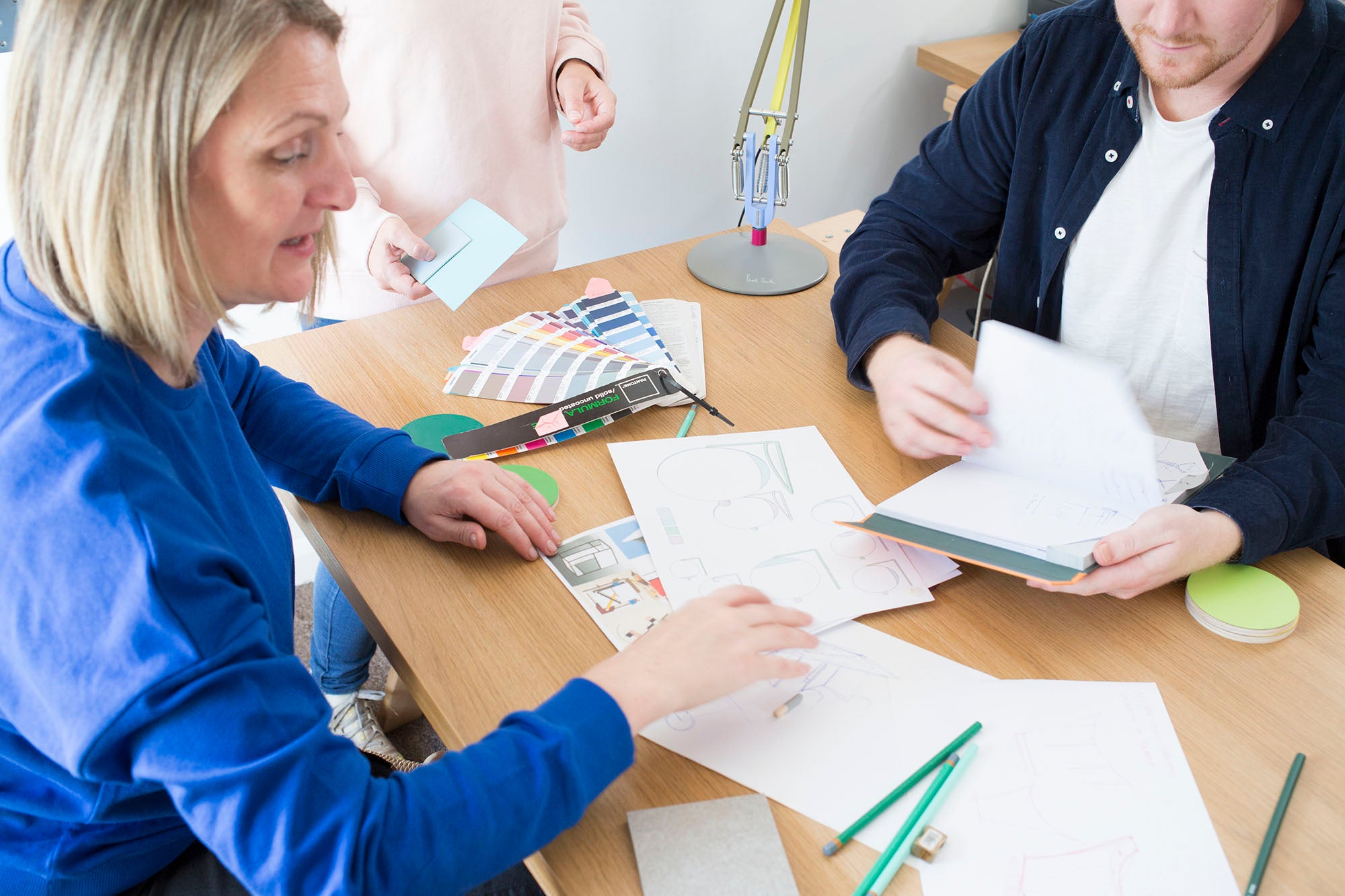

As with all of our designs the Tile Collection began life in Tara's sketchbook.

The collection is inspired by iconic tile work found throughout the art deco movement, particularly those found in East Coast America.

To get rough idea of scale, our product designer Ash then interprets Tara's sketches digitally to bring each piece to life on screen.

Having worked meticulously on the proportions of each product, Ash uses fusion 360 (CAD) to create a model in 3D space.

This is then sent to our in-house 3D printer to model using PLA (Polylactic acid, a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane).

Next the PLA model is filled and primed to remove any defects or blemishes, leaving a perfectly smooth surface.![]()

We use silicon to make moulds from the finished models. Mould walls are created from ply wood and placed around the model into which we pour in the silicon.

Once they are set they are delightfully wobbly - we can't resist a quick squidge as we walk past! (Much to Ash's frustration if they're not quite set... sorry Ash).

Now it's time to mix the Jesmonite resin and add our desired colour pigment. Jesmonite works so well with our design ethos that puts colour at the centre - the material can be finished with beautifully subtle hues.

Top tip from Ash - to ensure the colour in the final products is consistent he suggests adding the pigment to the liquid Jesmonite in the container it’s shipped in - this way measurements will be exact.

So now it's the hugely satisfying 'casting’ using the silicon moulds. We pour the Jesmonite into the negative space within the moulds to cast the final product.

To reduce bubbles Ash built a custom vibrating table that shakes the moulds as he pours the Jesmonite to break any air pockets that might have formed.

Jesmonite's source material is natural and so is considered sustainable. The base powder part is made from a natural sulfate mineral, the resin part is water-based. The collection is made in-house and uses very little energy, the liquid Jesmonite takes 20 minutes to set firm in room temperature.

Finally time for the finishing touch!

And there you have it, another product handmade and ready to use. Please click here to shop our Jesmonite Tile Collection.